Workers are at the highest risk in any job site, whether it is a construction industry, oil and gas industry, power plants, or refineries. Working in the oil and gas extraction industry comes with risks every year. Such workers experience injuries and fatalities on the job, and they’re at the greatest risk in the U.S. annually. Oil and gas safety standards are certainly important.

Employers and employees should be mindful and intentional about safety issues in oil and gas industry. We understand the constant pressure that comes with production and efficiency. We understand that drilling projects are expensive, time-sensitive, and physically demanding. All of this can take its toll on health and safety in the oil and gas industry today.

RISKS AT REFINERIES, POWER PLANTS, OIL AND GAS INDUSTRIES AND GENERAL CONSTRUCTION SITES

As most of the work at construction sites is physical, plenty of things can go wrong. Most dangers are unknown, which workers face daily in oil refineries. A few are easily detectable and correctable, but some are not. Some of these risks are discussed below:

Falls - Every time, construction site worker is at high risk of falls. The most common jobs resulting in this type of injury are cranes, scaffolding, ladders, roofs, and other mechanical work at heights.

About one-third of fatalities in construction are fall-related, and most are from roofs, ladders and scaffolding. As many as five construction workers a week are killed in falls. In fact, falls are the No. 1 cause of work-related deaths for construction workers.

Falling Objects - The risk of injuries to workers is exceptionally high when objects fall on them from the height. This may include working tools and unsecured construction material.

Objects and tools dropped from higher levels is a serious hazard for many worksites. In 2016, there were 255 workplace fatalities due to falling objects in the United States. Furthermore, OSHA estimates that over 50,000 “struck-by a falling object” incidents occur each year on construction sites alone.

Objects as small as a bolt can cause serious injury or even death when dropped from a higher level and striking an employee working on the ground. Outside of injuries and deaths, dropped objects are responsible for a large cost to employers due to property damage incidents as well.

Equipment Related Injuries - Short circuit, electrical shock, and unexpectedly start among the most common injuries related to equipment. Forklift injuries, Overloading dumpsters, and unexpectedly discharge of nail guns can also affect adversely.

Electric power generation plants maybe nuclear power plants and wind turbines or coal-burning plants and hydroelectric dams. Each has numerous hazards.

- Electrocution - Electric shock is common among other power plant dangers. Corrosive chemicals can result in electrical fatalities. Electrical shock may result in serious accidents.

Crushed between or backed over - The risk of being hit by any truck or car always remains for the workers at the worksite.

Heavy machinery on jobsites poses risks to construction workers and jobsite visitors every day. In addition to the risks of machinery rollovers, workers face the risk of being pinned under or crushed between heavy machinery and other equipment, or between heavy machinery and large beams. Sadly, these accidents often result in catastrophic injuries and death

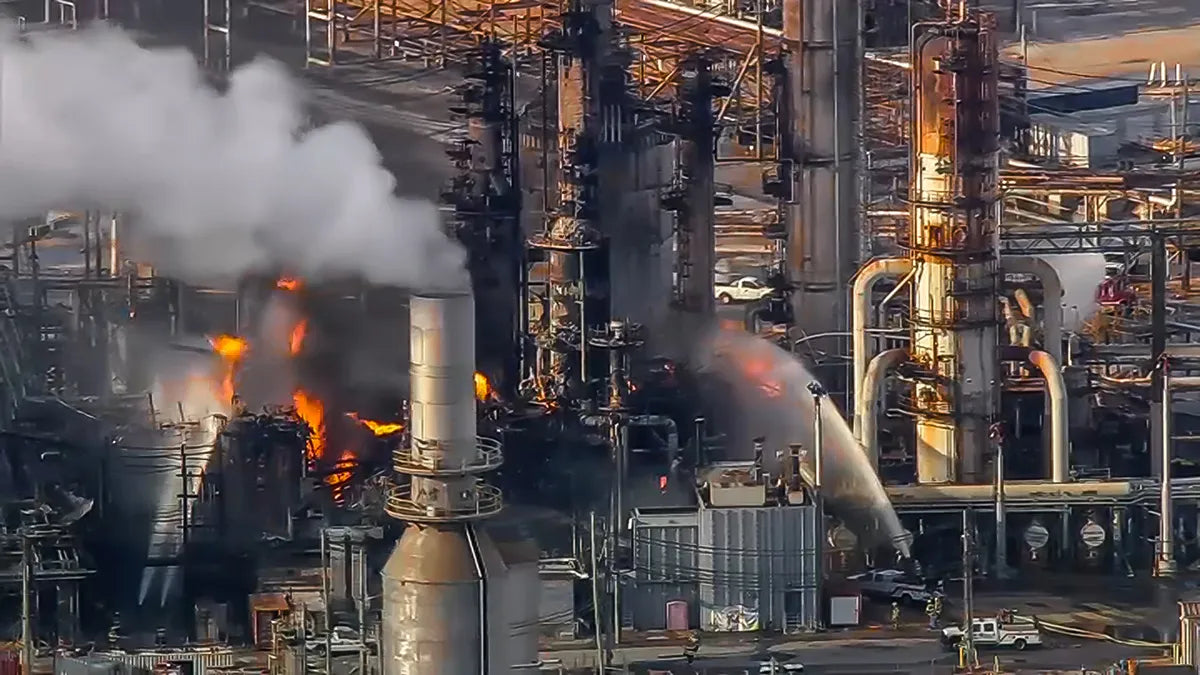

Fires and Explosions - These mishaps may result from flammable chemicals, leak pipes, exposed wires, or gas accumulation in an enclosed chamber.

- Polluted Air - This is quite a common problem in refineries, as they liberate dangerous chemicals such as toluene, benzene, xylene, and ethylbenzene. Others include NO, CO, SO2, AND H2S, which are equally harmful if inhaled regularly.

- Acid Risk - It is the most dangerous risk of all. Refineries work with high acidic chemicals like hydrofluoric acid.

Contractors are responsible for developing fire prevention and fire protection programs on their job sites. While fires on construction sites are not common, they still happen. Most fires are small and localized in nature, but without the proper precautions they can cause significant damage and even loss of life.

Confined Spaces - This may result in suffocation. It also leads to severe respiratory problems of exposure time is extended.

Chemical Exposures - Some highly toxic and explosive chemicals may result in the affected nervous system, respiratory paralysis, and irregular heartbeat.

Construction accidents on jobsites are incredibly common, but also completely avoidable. Unfortunately, construction sites are littered with different safety hazards and are the cause of numerous serious injuries, and in the most severe cases, fatalities. Construction sites are often filled with a combination of equipment, machinery, trucks, materials and various employees going about their work simultaneously.

Also, inherent on jobsites is the potential for falling debris and unsafe or uneven work surfaces. Although construction sites can sometimes be dangerous for workers, there are strategies that can be enacted to ensure injuries are kept to a minimum. This article goes over these tips that project managers can implement to reduce accidents and create a safer work environment for all.

Daily safety meetings: Employees need to be briefed about the different safety measures when it comes to each specific jobsite. As a project continues to progress, the hazards also change. It is up to project managers and team leaders to ensure that everyone on the jobsite is provided with proper instruction, and is aware of the changing regulations. Holding daily safety meetings ensures that everyone is kept up-to-date and is on the same page. Employees should also be told to keep safety as their prime concern. These meetings should also reiterate health and safety standards and proper risk assessment.

Reduce the amount of night work: Late work hours and dark environments create a greater potential for accidents. If possible, minimize the amount of night work, or limit it to a low-risk area of the jobsite. Some of the reasons why accidents increase at night include fatigue, as people are less alert after midnight, as well as reduced visibility. This combination creates the threat of more accidents, all of which are avoidable.

Proper safety gear: Construction sites are notorious for unpredictable accidents and unforeseen safety hazards. To prepare workers, proper protection is needed at all times. Some basic safety precautions include hardhats, eye protection, hearing protection and harnesses. Slip-resistant boots, heavy duty gloves and masks are also standard safety apparel that must be worn on all job-sites.

Reflective or highly-visible clothing: These are a must in order to reduce vehicle-related accidents. High reflective fabric should be used by all employees, and at all times. Through simply being seen by drivers and equipment operators, workers are kept out of harm’s way, which can reduce the potential of getting hit.

Regular and frequent breaks: Enforcing regular breaks are crucial in not only productivity, but safety as well. Frequent breaks allow workers to re-energize by drinking fluids, eating snacks and resting. This helps them to remain focused, alert and avoids fatigue and mistakes which can occur due to exhaustion.

Clear signage to warn of danger: Wires and high voltage areas should be marked and the electricity should be deactivated when it is not in use. Areas should be cordoned off by pylons and ropes – to prevent people accidentally moving into areas where there are chances of falling debris or other dangerous hazards. Simple signs with words like ‘Danger’ are incredibly simple, but are essential in ensuring safety.

Introduce a warm-up or calisthenics exercise: Before starting the day, workers should start with warm up or calisthenics exercises to keep the body fresh and agile as well as ensure the workers are fit for physical activity. This also helps them develop quicker reflexes as well as sharper minds.

Avoid sunlight to minimize fatigue: Exposed skin needs to be covered up. Wide brimmed hard hats, long sleeved shirts and other skin protectors need to be used. Direct sunlight is one of the main causes of fatigue. Taking care of this will ensure that workers ensure maximum amount of productivity in addition to reducing fatigue.

Practice defensive driving/parking/backing up: For vehicle and machine operators, vehicle warning strobes are needed to warn approaching traffic. Pylons, barrels, buffer zones, safety spotters and daytime running lights are needed. Drivers should be made to slow down and to avoid backing up whenever possible. If backing up is needed, a spotter should be assigned.

Be aware of worker diets; encourage healthy eating: Carbonated Sodas and energy drinks should be replaced with water, citrus drinks and electrolyte replacements. These help to hydrate the workers, reduce fatigue and increase concentration. In warm weather, light and grease-free food like salads and sandwiches, vegetables and fruits should be consumed rather than carb heavy and high-fat food. This prevents drowsiness after meals, and helps workers remain alert and energized.

Many of these tips require a great deal of training, encouragement and repetition to ensure that all workers are on board. Being consistent in practicing these tips will help create a culture of teamwork among all employees. Furthermore, these tips are built on elements of collaboration and commitment, which ensures a safer work environment for all.