Your FR clothing can be expensive to replace, so keeping it in service as long as possible without significantly sacrificing it’s protection is the goal. In addition to protection, other considerations for FR workwear includes comfort and appearance.

At some point during the life of any FR garment, it is necessary to consider removing it from service due to basic wear and tear. Although most recognized brands of FR fabric are made to maintain their flame resistance for the life of the garment, physical damage may also dictate the need to remove them out from service. For most practical purposes, garments may be removed from service based on subjective evaluation if, after regular inspections, the garment is found incapable of effectively protecting the wearer. Ultimately, it is the end user’s responsibility to put that FR on retirement.

Part of the garment’s ability to protect is the simple fact that the fabric provides a barrier from hazardous conditions. The weight or mass of the fabric can make a difference in the level of thermal protection provided too. The following points, identifiable by visual examination, may diminish the effectiveness of FR clothing and are cause for removing them from service or at least evaluating them for possible repair.

1. Worn appearance – Replace garments that have thin spots, holes, noticeable burns or excessive wear and abrasion, such as elbow or knee areas that can no longer be repaired.

Nexon FR clothing are known for reinforced stitching that prevents this damage and prolong the life of your FR clothing, but evaluating time to time does not hurt and if wears are excessive, it is time to remove them in service.

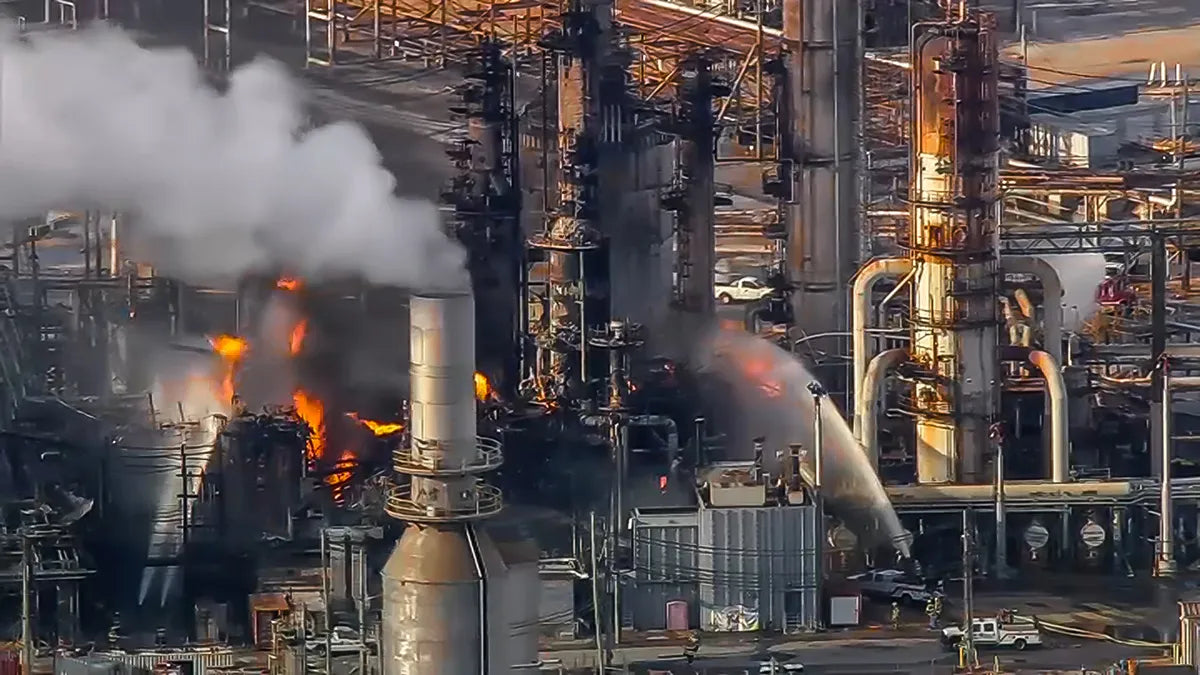

2. Heavily soiled – If there are flammable substances on a garment that cannot be removed by cleaning; such as solvents, solids, oils and other petroleum products then those substances represent a flammability risk. Note that the presence of a petroleum or chemical odor can be evidence of a flammable substance. Clothing soiled with combustible or flammable chemicals should be handled by qualified individuals, using techniques approved for such materials, and in accordance with pre-established procedures. Failure to fully remove these chemicals will definitely compromise your FR clothing’s effectiveness.

3. Mechanical damage – Evidence of cuts, rips, tears, open seams and nonfunctional closures that can no longer be repaired indicate a garment needs to be replaced.

4. Noticeable alteration – Garments that have been modified or altered in a manner that differs significantly from the original design should be removed from service.

Please read more about how to properly alter or repair FR clothing here: https://bit.ly/34ZykTw

5. Improper fitting – If the garment is either too big or too small for the wearer, it should be replaced. If the garment is too big it can be a physically hazardous, and if the garment is too small it loses some of its thermal protection you need. FR clothing should have a looser fit to allow the air gap between the wearer and the garment to help with insulation. That is the main reason why Nexon FR shirts runs larger than normal fitting. Please see our size chart here: https://bit.ly/3nTSfvS

If the garment has obvious damage that could be repaired, being able to properly repair a damaged clothing can be an effective way to reduce expenses. However, here are a few basic guidelines should be followed to effectively repair FR clothing:

- Always make repairs using fabric consistent with the garment’s original fabric. Using same FR rated repair fabrics is a must. Other fabric types may react differently to both thermal exposure and laundering.

- Use inherently FR thread for any repair. Use of non-FR thread can compromise the performance of the garment. Non-FR thread can burn quickly, allowing the sewn area to come apart and expose flammable under-layers or bare skin, which could lead to burn injury.

- When adding or repairing other components, such as zippers, buttons, knit cuffs, draw strings, reflective tape, etc., they should also be rated as FR or in the case of buttons or at least high-temperature rated. These components may seem minor, but non FR versions can compromise the effectiveness of your FR clothing during an exposure.

In addition to protection, the comfort and appearance of your clothing should also be considered. If wearers know their FR garments are guaranteed to be flame resistant for life even if they are threadbare, have holes or tears, or don’t fit properly — they might find such garments unpleasant to wear. Having fully functional, clean, well-fitting FR garments makes for a safer workplace environment, with workers who take care of their garments as well as other PPE.

Make sure to inspect your FR garments on a regular basis, repair them when necessary, and replace them when they are irreparable and fail to serve their primary purpose of protecting you.